VOM FEIN- UND SANDGUSS ÜBER DAS CNC-DREHEN UND -FRÄSEN BIS HIN ZUR MONTAGE

Rundum betreut – Wolfensberger ist vom ersten bis zum letzten Schritt Ihr Ansprechpartner für anspruchsvolle Stahlgussprodukte.

FEINGUSS MIT CERACORE® UND EXACAST®

Konventioneller Feinguss war gestern…

Kurze Lieferzeit, hohe Oberflächengüte, ganz ohne Wachs…CERACORE® SHELF

Vollkeramisches Feingussverfahren

Im Ceracore® SHELF-Verfahren erzeugen wir Kernpakete mit vollkeramischen Formen und Kernen. Durch unsere automatisierten Fertigungslinien sind wir in der Lage schnell, kostengünstig und flexibel auf Ihre Produktwünsche einzugehen.

Gegenüber dem klassischen Wachsausschmelzverfahren besticht das Ceracore® SHELF-Verfahren mit einer Durchlaufzeit von gerade mal 2 bis 3 Arbeitstagen für Formherstellung und Abguss.

CERACORE® HYBRID

Das Beste aus 2 Welten – Sandgussverfahren mit keramischen Inlays

Beim Ceracore® HYBRID-Verfahren erzeugen wir hybride Kernpakete. Konturen mit regulären Ansprüchen an Genauigkeit und Oberflächengüte aus Kernsand, hoch komplexe Teilbereiche mit hohen Oberflächengüten aus keramischen Kernen. Oft werden Bauteile komplett im Feinguss hergestellt, obwohl nur kleine Bereiche des Bauteils die hohen Oberflächeneigenschaften des Feingusses benötigen.

EXACAST®

Wo Feinguss an seine Grenzen stösst…

Im Exacast®-Verfahren werden Bauteile, die wegen ihres hohen Gewichtes, ihrer grossen Dimension oder dünner Wandstärke nicht im Feinguss erzeugt werden können, vollkeramisch im Kernpaket hergestellt. Hierbei wird mit keramisch beschichteten Feuerfestformen gearbeitet, in welche bei Bedarf keramische Kerne zum Einsatz kommen.SANDGUSS

Individuelle, vielfältige Produktlösungen

Stahlguss ab Losgrösse 10, kostengünstiges und schnelles Änderungsmanagement, über 100 Legierungen, für kleine bis mittlere LosgrössenHANDFORMGUSS

Furanharz-Verfahren

Kastengeometrie

- Grösster Kasten 2’000 x 2’000 mm

- Kleinserien 1 bis 10 Stück

- Teilegewichte von 5 bis 800 kg (Rohgussgewicht)

- Bis zu 100 Eisen- und Stahlgusswerkstoff

TEILAUTOMATISCHE FERTIGUNG

Kaltharz-Blockformanlage

Kastengeometrie- Ballengrösse 1200 x 1200 x 840 mm

- Losgrösse ab 10 Stück

- Teilegewichte von 5 bis 200 kg (Rohgussgewicht)

- Bis zu 100 Eisen- und Stahlgusswerkstoffe

KERNBLOCKVERFAHREN

Resol-CO2-Verfahren

Kastengeometrie

- Maximale Kernpaketgrösse 800 x 800 x 400 mm

- Losgrössen mindestens 50 Formen

- Teilegewichte von 1 bis 50 kg (Rohgussgewicht)

- Bis zu 100 Eisen- und Stahlgusswerkstoffe

ROHLINGE FÜR CNC-DREHEN UND -FRÄSEN

Sie wollen Ihre CNC-Maschinen effizienter nutzen?

Insbesondere bei teuren Legierungen und langen Bearbeitungszeiten lohnt sich der Einsatz von vorgegossenen Rohlingen.HALBZEUGE (Zylinder, Rohre, Quader)

Kürzere Bearbeitungszeiten und weniger Verschnitt durch vorbearbeitete Rohlinge

Vorbearbeitung von Rohlingen auf Mass nach Kundenwunsch3D-GEOMETRIE

Individuelle Formgebung

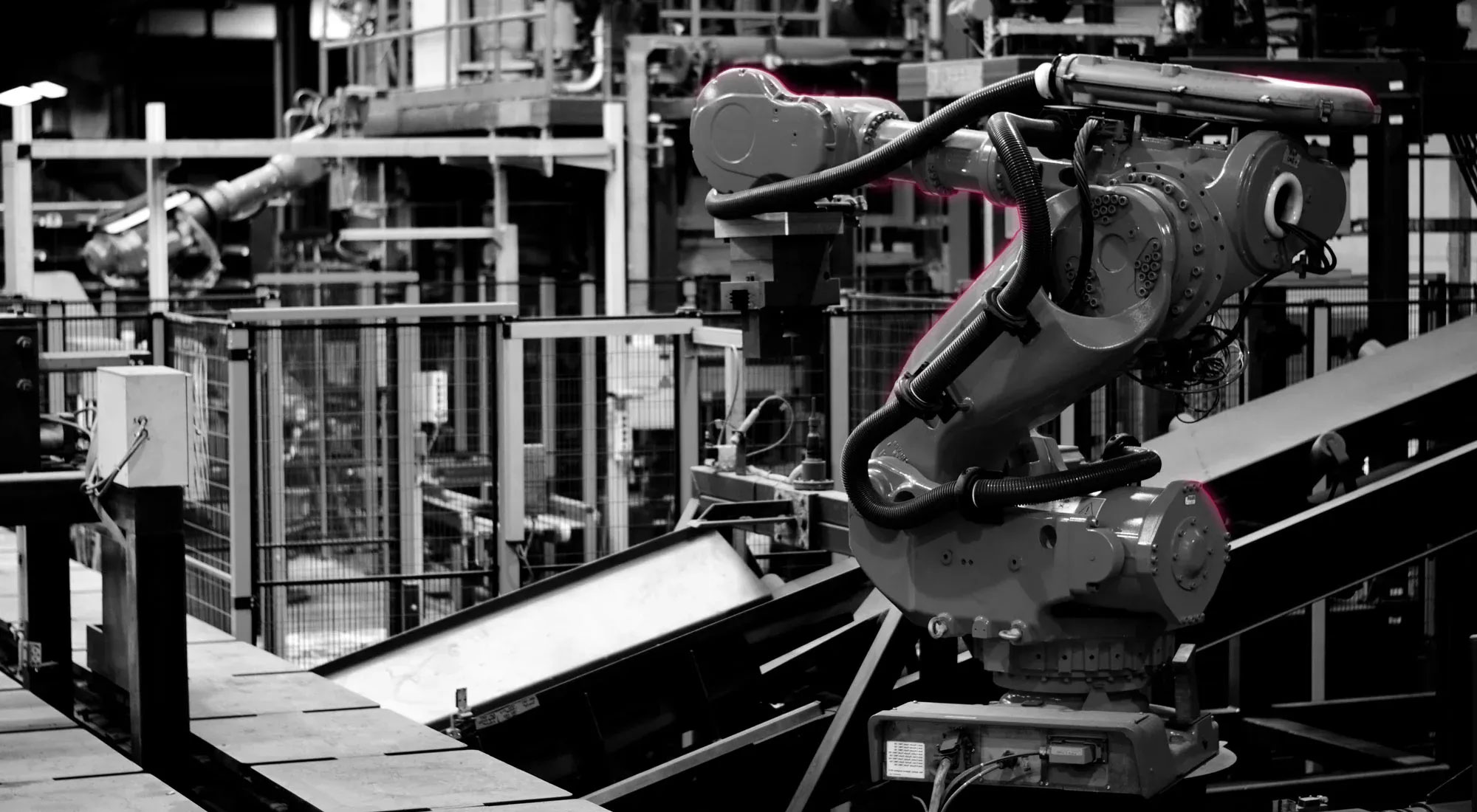

Gegossene Rohlinge in frei geformten Volumen, massgenau und individuell nach KundenspezifikationenCNC-DREHEN UND -FRÄSEN

Anspruchsvolle Werkstoffe, höchste Anforderung an Präzision

Zerspanung anspruchsvoller Werkstoffe, komplexe Bauteilgeometrien, zeitkritische Ersatzteilfertigung…DREHEN

Horizontale- und vertikale Drehzentren

Rotierende Bearbeitung schwer zerspanbarer Teile, bis zu einem Durchmesser von 1200 mm. Durch unsere langjährige Erfahrung in der Bearbeitung schwer zerspanbarer Materialien sowie den Einsatz äusserst stabiler Maschinen garantieren wir Ihnen die Einhaltung anspruchsvoller Toleranzen und eine hervorragende Oberflächengüte.FRÄSEN

Stabile Mehrachsfräszentren für besondere Bauteile

Kubische Bearbeitung von Stahl, Sphäroguss aber auch schwer zerspanbarem Hartguss, von kleiner bis mittlerer Dimension. Hohe Produktivität durch Pendelbetrieb und Mehrfachaufspannung für Bearbeitung kleiner und mittlerer Losgrössen.SCHLEIFEN

DER Feinschliff für Ihre Teile

Mass- und formgenaues Flach-, Einstech- und Profilschleifen von sehr harten und zähen Materialien wie verschleissfeste Stähle, Hartmetalle und Keramiken mit unseren Flach- und Profilschleifmaschinen.MONTAGE UND DIENSTLEISTUNG

Sie suchen einen Generalunternehmer für Ihre komplette Baugruppe?

Aufwendige Disposition von Zukaufteilen, Zusammenbau kompletter Baugruppen, Unterstützung beim Engineering…Lernen Sie die Werkstoffe und Anwendungen unserer Giesserei kennen!

Noch mehr Informationen über unser breites Angebot an Leistungen und Produkten rund um den StahlgussANGEBOT

JETZT ANFRAGE SENDEN

Teilen Sie uns mit, welche Art von Produkt Sie benötigen und wir kümmern uns unverzüglich darum, einen Plan zu erstellen und Ihnen ein unverbindliches Angebot zukommen zu lassen.