FROM INVESTMENT AND SAND CASTING, CNC TURNING AND MILLING TO ASSEMBLY

We offer you an all-round service: Wolfensberger is your partner for sophisticated cast steel products from the first to the last step.

INVESTMENT CASTING WITH CERACORE® AND EXACAST®

Forget about conventional investment casting…

Short delivery times, high surface quality, without having to use any wax…CERACORE® SHELF

All-ceramic investment casting process

In the Ceracore® SHELF process, we produce core packages with all-ceramic molds and cores. Our automated production lines enable us to respond quickly, cost-effectively and flexibly to your product requirements. Compared to the traditional wax melting-out process, the Ceracore® SHELF process impresses with a lead time of just 2 to 3 working days for mold production and casting.CERACORE® HYBRID

The best of both worlds – sand casting process with ceramic inlays

In the Ceracore® HYBRID process, we produce hybrid core packages. Contours with regular requirements for accuracy and surface quality are made from core sand, while highly complex sub-areas with high surface qualities are made from ceramic cores. Components are often manufactured entirely by investment casting, although only small areas of the component require the high surface properties of investment casting.EXACAST®

This is where investment casting reaches its limits…

This is where investment casting reaches its limits… In the Exacast® process, components that cannot be produced by investment casting due to their high weight, large dimensions or thin wall thickness are manufactured fully ceramic in the core package. In this process, ceramic-coated refractory molds are used in which ceramic cores are inserted as required.SAND CASTING

Individual, versatile product solutions

Steel castings from batch size 10, cost-effective and fast change management, more than 100 alloys, for small to medium batch sizesHAND MOLD CASTING

Furan resin process

Box geometry

- Largest box 2,000 x 2,000 mm

- Small batches 1 to 10 pieces

- Part weights from 5 to 800 kg (raw casting weight)

- Up to 100 iron and steel casting materials

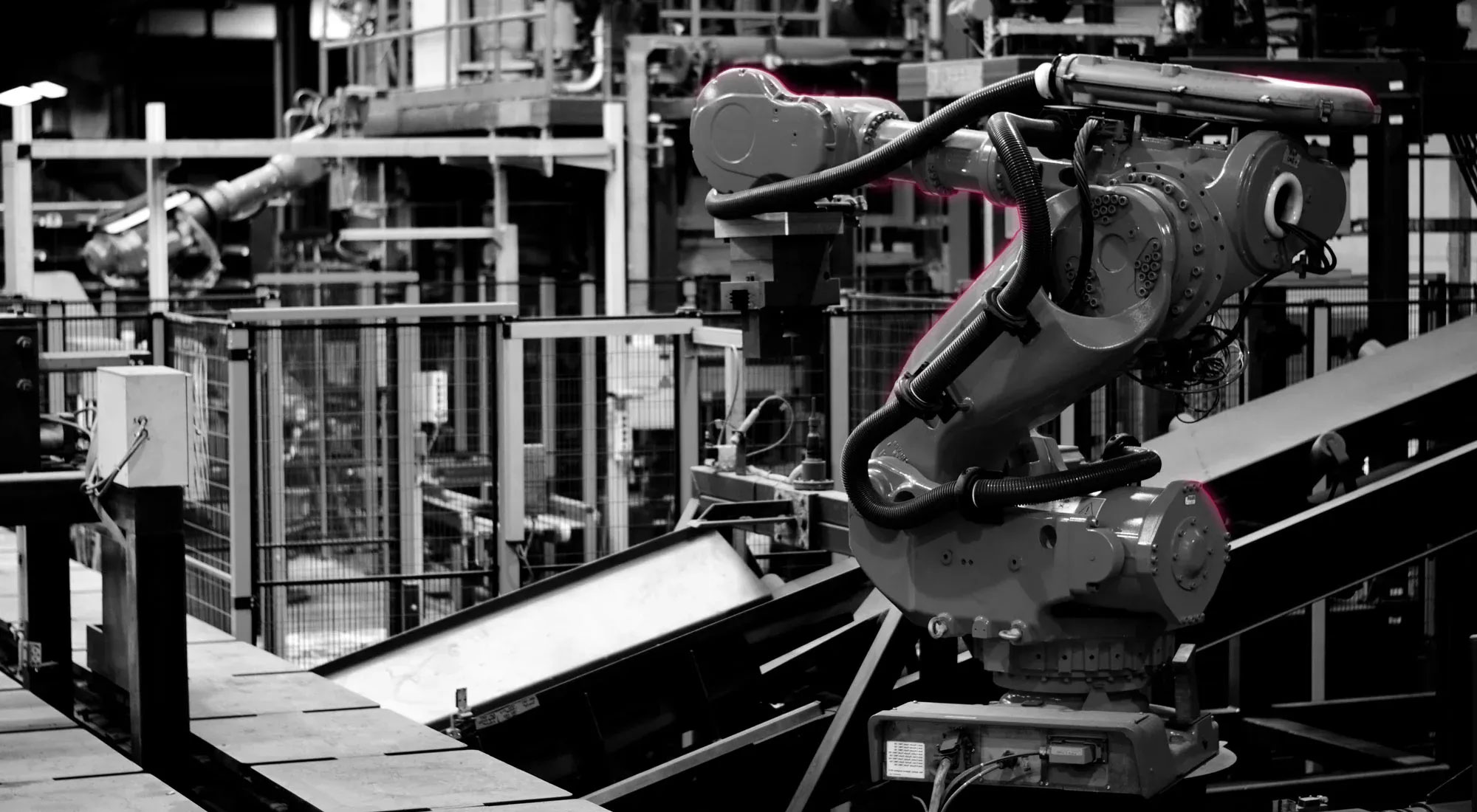

SEMI-AUTOMATIC PRODUCTION

Cold resin block molding machine

Box geometry- Bale size 1,200 x 1,200 x 840 mm

- Batch size from 10 pieces

- Part weights from 5 to 200 kg (raw casting weight)

- Up to 100 iron and steel casting materials

CORE BLOCK PROCESS

Resol-CO2-process

Resol-CO2 process

- Maximum core package size 800 x 800 x 400 mm

- Batch sizes of at least 50 molds

- Part weights from 1 to 50 kg (raw casting weight)

- Up to 100 iron and steel casting materials

BLANKS FOR CNC TURNING AND MILLING

Do you want to use your CNC machines more efficiently?

Especially for expensive alloys and long machining times, the use of pre-cast blanks pays off.SEMI-FINISHED PRODUCTS (cylinders, tubes, cuboids)

Shorter machining times and less waste due to pre-machined blanks

Pre-machining of blanks to size according to customer requirements.3D GEOMETRY

Individual mold shaping

Cast blanks in individually shaped volumes, accurate to size and individual according to customer specificationsCNC TURNING AND MILLING

Demanding materials, highest precision requirements

Machining of demanding materials, complex component geometries, time-critical spare parts production…TURNING

Horizontal and vertical turning centers

Rotating machining of difficult-to-machine parts, up to a diameter of 1200 mm. Our extensive experience in the machining of difficult-to-machine materials and the use of extremely stable machines guarantee compliance with demanding tolerances and excellent surface quality.MILLING

Stable multi-axis milling centers for special components

Cubic machining of steel, nodular cast iron but also difficult-to-machine chilled cast iron, from small to medium dimensions. High productivity due to pendulum operation and multiple clamping to machine small and medium batch sizes.GRINDING

The finishing touch that YOU need for your parts

True-to-size and true-to-shape surface, plunge and profile grinding of very hard and tough materials such as wear-resistant steels, hard metals and ceramics with our surface and profile grinding machines.ASSEMBLY AND SERVICE

Are you looking for a general contractor for your complete assembly?

Complex disposition of purchased parts, assembly of complete subassemblies, engineering support…GET TO KNOW THE MATERIALS AND APPLICATIONS OF OUR FOUNDRY!

Read more about our wide range of services and products related to steel castingQUOTE

SEND YOUR REQUEST NOW

Let us know what kind of product you need and we will immediately create a plan and send you a non-binding quote.